Products

Liquids, Creams and Ointments:

Lepharm and its partners has manufacturing facilities dedicated to the production of Liquids, Creams and Ointments. A broad range of formulations, batch sizes and packaging formats can be accommodated.

Liquids and Creams

• Syrups, suspension, creams , ointments and lotions

Liquids filling:

• Syrups, suspension, creams , ointments and lotions

Liquids filling:

- Plastic and glass bottles

- Caps, nasal sprays and pumps.

- “Fill by weight” technology.

- Dual side labeling , auto change over.

- Shrink seal application.

- Metal, HDPE, Metal and Plastic laminate.

- Multiple size filling capability.

Solid Dose Formulations:

Lepharm and its partners offers a broad range of capabilities for solid dose production

- Batches from 50 kg to 2000 kg.

- Tablets (coated and uncoated), Capsules.

- Wet granulation (tray or fluid bed dry).

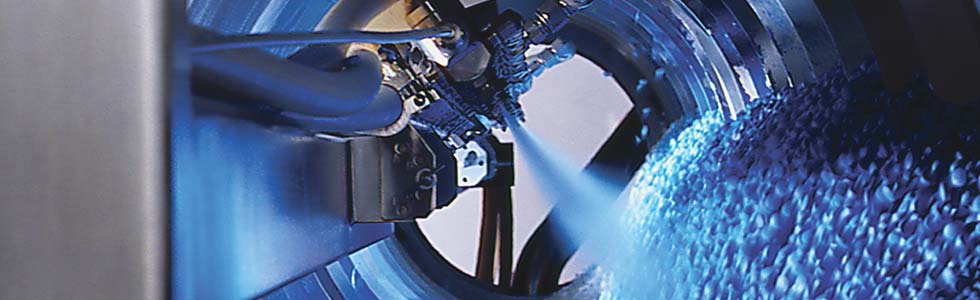

- Fluid bed spray granulation.

- Direct Compression.

- Solvent and aqueous coating.

- Innovative technology of gelatin-coated tablets, that replace the traditional two piece hard gelatin capsules.

- Encapsulation.

- Sachet filling

- nutritional powdered supplements

- Blister packs in a wide range of formats of film/aluminum plus cold form (aluminum).

- Bottles, glass and plastic.

- Sachet filling

- pouches and single dosing formats

Sterile and Injectible solutions:

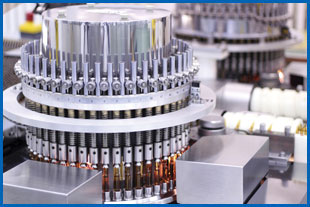

Lepharm offers private label contract solutions for different sterile and injectable products. Our partners are regularly manufacturing injectable ampoules and vials for third party companies. By contract manufacturing with us, you will benefit from tens of years of expertise in the sterile manufacturing of injectable products.

To reach the top quality in pharmaceutical manufacturing of infusion solutions, it is essential to strictly follow the processes and have a deep knowledge of the materials used .The very latest technologies in terms of filling machines, quality control equipments and packaging machines are utilized. This enables us to positively answer most of the market requirements by offering the right pharmaceutical form with the right volume. Either in vials or in ampoules , in plastic or in glass, we offer a vast portfolio of volumes and packaging possibilities.

From the filling to the packaging, we can offer you pharmaceutical contract manufacturing services for the following pharmaceutical forms : glass ampoule, polypropylene ampoule (blow fill seal manufacturing technology), polyethylene ampoule (bfs technology) and glass vial.

To reach the top quality in pharmaceutical manufacturing of infusion solutions, it is essential to strictly follow the processes and have a deep knowledge of the materials used .The very latest technologies in terms of filling machines, quality control equipments and packaging machines are utilized. This enables us to positively answer most of the market requirements by offering the right pharmaceutical form with the right volume. Either in vials or in ampoules , in plastic or in glass, we offer a vast portfolio of volumes and packaging possibilities.

From the filling to the packaging, we can offer you pharmaceutical contract manufacturing services for the following pharmaceutical forms : glass ampoule, polypropylene ampoule (blow fill seal manufacturing technology), polyethylene ampoule (bfs technology) and glass vial.

Support Services Our contract customers have the option of Lepharm providing al l or part of the support services associated with the production

Services offered include:

- Analytical and Microbiological testing from highly equipped trusted facilities with the latest technology.

- Validation – process and analytical.

- Stability programs

- Product development

- Marketing materials